In the production process of aluminum foil, it has to go through multiple processes such as rolling, finishing, annealing, and packaging. In the interlocking production process, any problem in any link may lead to quality problems of aluminum foil. Quality defects of purchased aluminum foil products will not only affect the appearance, but also directly affect the quality of the produced products, and even directly lead to the suspension of aluminum foil production, greatly affecting production efficiency. How to distinguish the quality of aluminum foil?

According to the experience of the aluminum industry, the quality of aluminum foil can be detected directly with "eyes". However, to distinguish the quality of aluminum foil, we must first understand what are the common quality defects of aluminum foil. Only when we have an inventory, and then check the common aluminum foil quality problems one by one, can we eliminate the aluminum foil with quality defects.

We have sorted out the comprehensive quality defects of aluminum foil in history. To help you distinguish between good and bad aluminum foil.

Aluminum foil bruising refers to the damage caused by the surface or end surface of aluminum foil colliding with other objects during transportation or storage. Most bruises are caused by carelessness while wrapping in foil.

2. Corrosion

The surface of the aluminum foil is in contact with the surrounding medium. After the chemical reaction or electrochemical reaction occurs, the defects on the surface of the aluminum foil will lose their luster, and in severe cases, gray corrosion products will also be produced. The corroded aluminum foil will have a great impact on the appearance of the products produced by the terminal.

3. Surface Bubbles

For aluminum foil with bubble defects on the surface, irregular circular or strip-shaped cavity protrusions will appear on the surface of the aluminum foil; the protrusions have smooth edges, asymmetrical sides, and irregular distribution. Air bubbles on the surface cause various spots to appear on the aluminum foil. Unbalanced forces are likely to cause breakage and downtime.

4. Dark Stripes

Dark surface streaks appear mostly on double frets. The dark surface has obvious light and dark stripe patterns along the rolling direction, which affects the appearance.

5. Mark

There are many situations that can cause marks on the surface of the aluminum foil, such as defective or sticky metal dust on the surface of the roller or guide roller, unclean or partially smooth protrusions on the surface of the sleeve or core, or foreign matter sticking to the surface of the rolled foil. The surface of the printed foil usually has single or periodic depressions or protrusions, which are easy to distinguish.

6. Oil Spots

Common aluminum foil oil stains are formed after annealing, generally in light yellow, brown, or tan.

7. Degreasing is Not Clean

Check that the skin is clean. Generally, after annealing, the degree of degreasing is detected by the water brush method. If the level specified by the water brush test is not reached, the aluminum foil may be oily.

8. Cracked Edge

The phenomenon that the longitudinal edge of the aluminum foil surface is broken is called a crack edge. In severe cases, obvious gaps can be seen on both sides.

9. Bad Shape

The unevenness of the foil surface due to uneven deformation is called bad shape. According to the location of the defect, it is divided into the medium wave, side wave, double rib wave, and composite wave. The waves at the edge are called edge waves, the waves in the middle are called intermediate waves, both are called complex waves, and double rib waves are neither in the middle nor at the edge.

10. Adhesion

Single foil rolls are not easy to open. When multiple sheets are opened, it is a knot. The free fall length of the product does not meet the standard requirements. In severe cases, the leaflet cannot be opened.

The above introduces the method of judging the quality of the aluminum foil. If you want to buy high-quality aluminum foil, please

contact us.

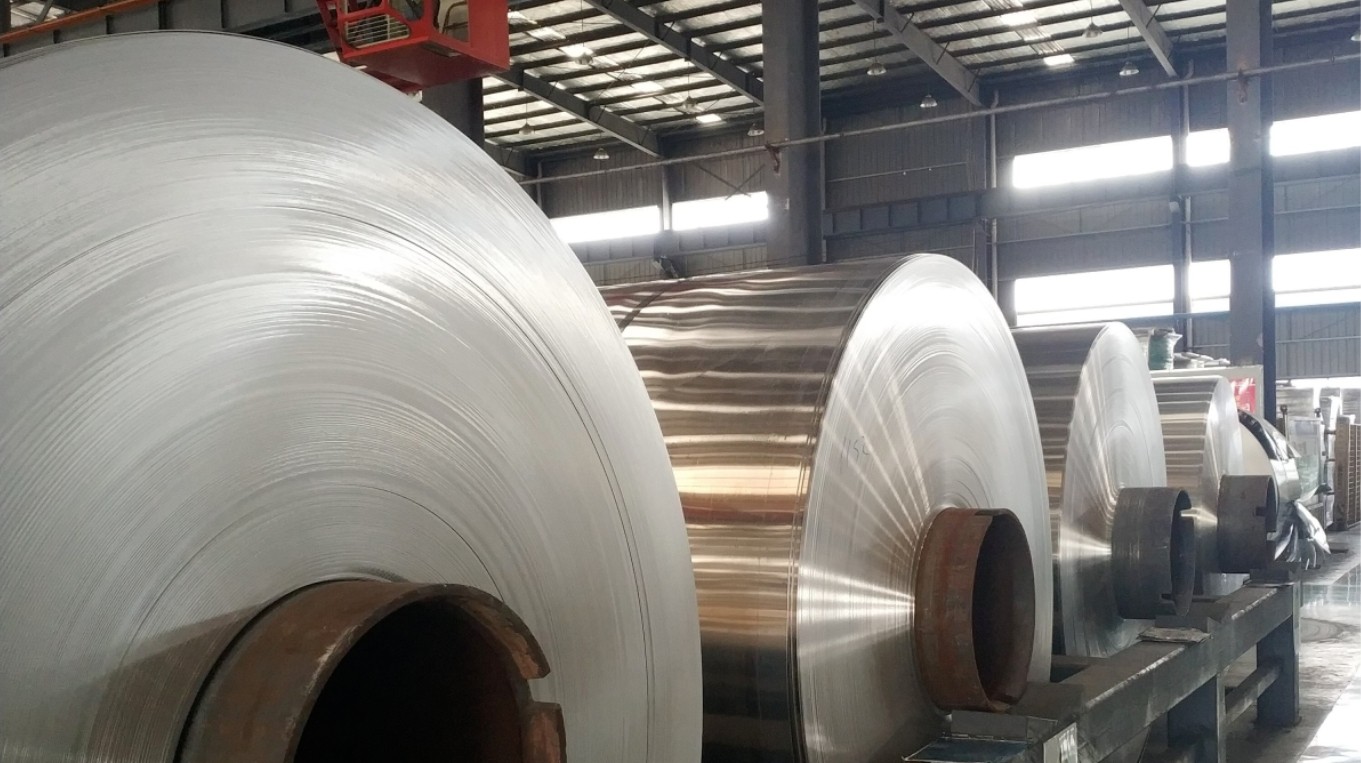

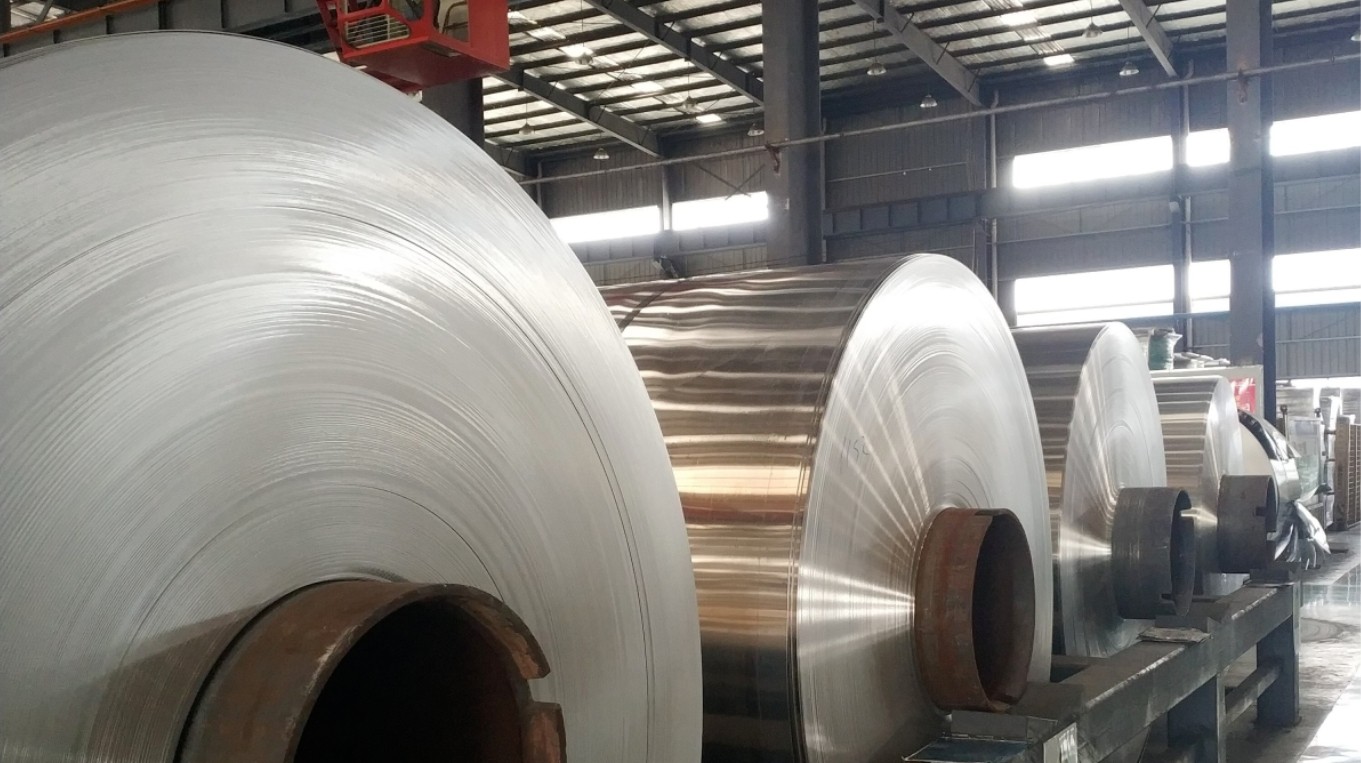

PENGYUAN is a professional

custom aluminum foil coating manufacturer. We have 3 vacuum coating machines and 8 PE extrusion coating production lines, guided by the 6S management system. As the largest extrusion coating base in China, the company has obtained ISO9001, ISO14001, and ISO45001 production standards for the whole system.