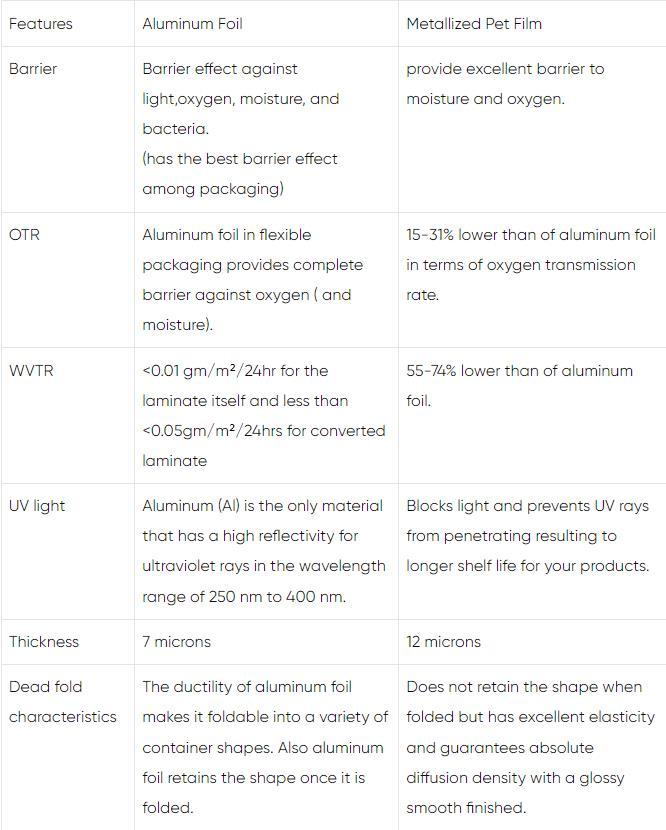

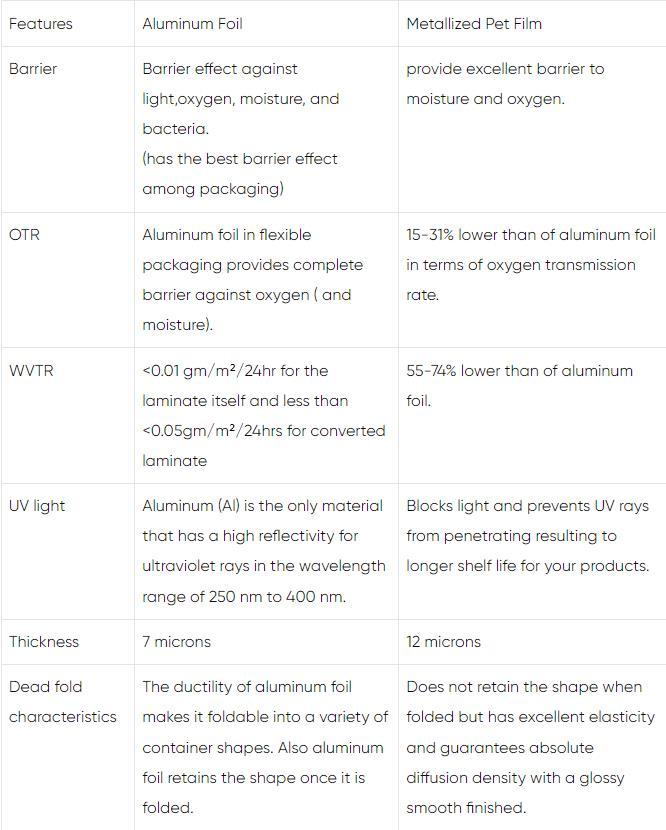

In summary, aluminum foil has the barrier functions of blocking moisture, blocking oxygen, blocking aroma, and resisting the influence of light. Thanks to its oxygen barrier, it prevents chemicals in food from reacting which can lead to off-flavors and rancidity. It is one of the most expensive layers in multilayer flexible packaging due to its barrier properties.

Metallized PET films are ideal for applications where flavor and freshness are required. This is suitable for packaging applications in the technical and industrial sectors. Read on to learn more about the difference between aluminum film and metalized PET film in flexible packaging.

How do Physically Distinguish Aluminum Foil and Aluminized Pet Film in Flexible Packaging?

There are various ways to distinguish them physically. For example, try shining light on aluminum foil and metalized PET film and see which will pass. If the light passes through the film, it is obviously a metalized PET film. Because it doesn't have an opaque barrier that prevents light from passing through. Unlike aluminum foil, which is made of sheet metal, light cannot pass through but only reflects.

Also in terms of appearance, the foil looks stiffer and has a matte finish compared to metalized PET. Metallized PET, it has a softer appearance and a glossy finish. When holding aluminum foil, it is lighter and more flexible than metalized PET film.

Lamination Fastness of Printed Film

In rigid packaging, we use multi-layer materials laminated with aluminum foil or metalized PET film. By doing so, we have to consider the lamination fastness of these films. Laminated aluminum foil film has good sealing ability, good chemical resistance, and water resistance. Offers the advantages of good oxygen barrier properties and good formability. This preserves the freshness of the product for longer.

The metalized PET film is coated with a thin layer of aluminum powder. Therefore, we cannot laminate metalized PET as we can on Bopp, PET, or Nylon films. Why? Because of the thin aluminum layer on the metalized pet. This will create chemical transfer between the layers, compromising the bag's fastness and stability.

How to Choose Aluminum Foil and Metallized Pet Film in Packaging?

If you are a CPG brand, do not have high requirements for shelf life, storage packaging, or need a special environment. Then MET PET is the answer for you, as an ideal foil replacement and cost-effective packaging solution. Products such as coffee, nuts, dried food, and energy drink powders are best suited for metalized PET films.

Due to the lightweight metalized PET film, more packaging units can be accommodated per square meter. In addition, with the continuous advancement of packaging technology, the demand for metalized PET film is increasing.

On the other hand, if your packaging requires special barrier properties or shielding capabilities to protect and extend the shelf life of your product, then aluminum foil is your best option. The efficient storage of food and beverages in aluminum packaging reduces the need for cooling effects and makes them slower to spoil.

Another benefit is that aluminum's light weight reduces the energy required during transportation. Aluminum foil works best on products like instant beverages, snacks, sausages, jerky, baby food, ready meals, and preserves. But demand for thinner foils is increasing due to high costs. Another thing to keep in mind is that aluminum reacts with acidic or salty foods and the aluminum ions dissolve and can get into the food.

Sustainable

The aluminum foil itself is a metal material made of thin aluminum sheets. Metallized PET, on the other hand, is a plastic part with a single layer or thin aluminum flakes. As I said before, the production of aluminum foil requires more energy, water, and greenhouse gas emissions than plastic film. But despite this, aluminum foil is recyclable. Flexible packaging using aluminum foil has a higher product-to-pack ratio than rigid packaging.

In addition, the aluminum material is fully recyclable, which increases the collection and recycling rate of aluminum foil. This means that less primary aluminum will be required. Processed recycled aluminum can deliver significant energy savings compared to virgin metal, requiring 95% less energy.

Metallized PET is based on polyester resin, so it can be recycled into other plastic products, reducing landfill waste. An environmentally friendly solution for recycling metalized pets has been developed. This means that met PET is recycled into PET pellets with enhanced physical, mechanical, optical, and aesthetic properties. The physical, mechanical, and aesthetic properties of tapes and yarns produced from a recycled met pet are comparable to virgin pet pellets.

In Conclusion

All in all, laminated metalized films provide enhanced barrier protection for your products. In food packaging, aluminum foil is usually laminated with plastic film. Using aluminum foil offers advantages such as being lightweight, water resistance, the reflection of heat and UV rays, and recyclability.

On the other hand, metalized PET is also very popular with food manufacturers. Because it maintains the freshness and flavor of the product. In addition, both films are scratch-resistant, protecting the product from packaging lines and environmental factors during transport. Provide high-quality and aesthetic finishes to your product packaging.

The above introduces the application and difference between aluminum foil and metalized PET film in detail. If you have any questions or want to buy, please pay attention and

contact us.

PENGYUAN is a professional

custom thermal insulation material manufacturer. We have 3 vacuum coating machines and 8 PE extrusion coating production lines, guided by the 6S management system. As the largest extrusion coating film base in China, the company has obtained ISO9001, ISO14001, and ISO45001 full-system production standards.